"Jitomyo" came from the word of Buddha which Nagaichi Suga cherished. It means "The light of my life is turned by myself, and the strength of the brightness is depended on my own efforts," and he pioneered weathering test instruments in Japan with his light.

I believe that in search of deterioration is the one of the approach to natural science. It is the duty that need to have a responsibility for what made by oneself.

(Cited from Nagaichi Suga, “Weather Resistance Light and Colour” Revised Edition)

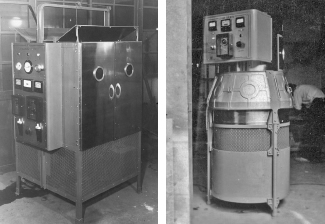

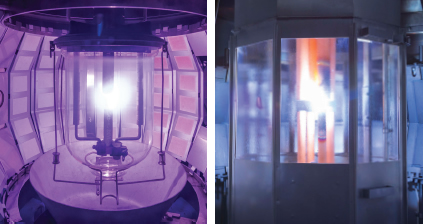

In the 1950s, weathering test instruments were imported from Europe and America. The Suga brothers learned the importance of weathering tests and then developed the first Japanese weather meter in 1952.

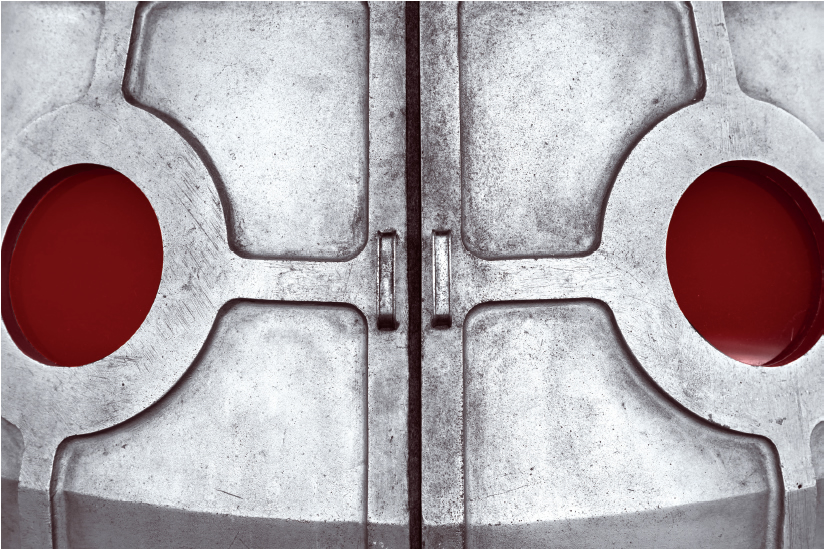

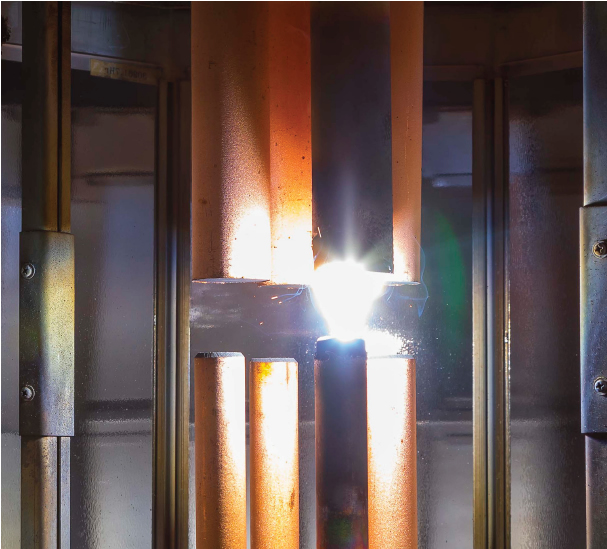

In the circuit for discharging the carbon, we attempted to meet the following 4 conditions mainly in the transformer: to reduce the ash caused by discharge; to keep the current and the voltage stable; to hold spectral irradiance constant; to maintain a lifetime for 24 hours. (omission)

We were taught measurement method of ultraviolet range of the radiation from Dr. Kyo Sekihara (the Meteorological Research Institute), the basic research on the radiation from Dr. Ryuichi Hioki (the University of Tokyo's physics class), and the energy measurement of discharge in electric circuits from Dr. Tsuneo Harada and Dr. Takashi Azuma (Toshiba Corporate Research & Development Center). These were important opportunities for us, and the knowledge helped us to contribute to society later so much.

(Cited from Nagaichi Suga, “Jitomyo No.2” The story of a weather meter)

The Suga brothers collected literatures and documents of light sources from either internal or external sources, and asked authorities in weathering field for support to start the research of an electric discharge for manufacturing weather meters.

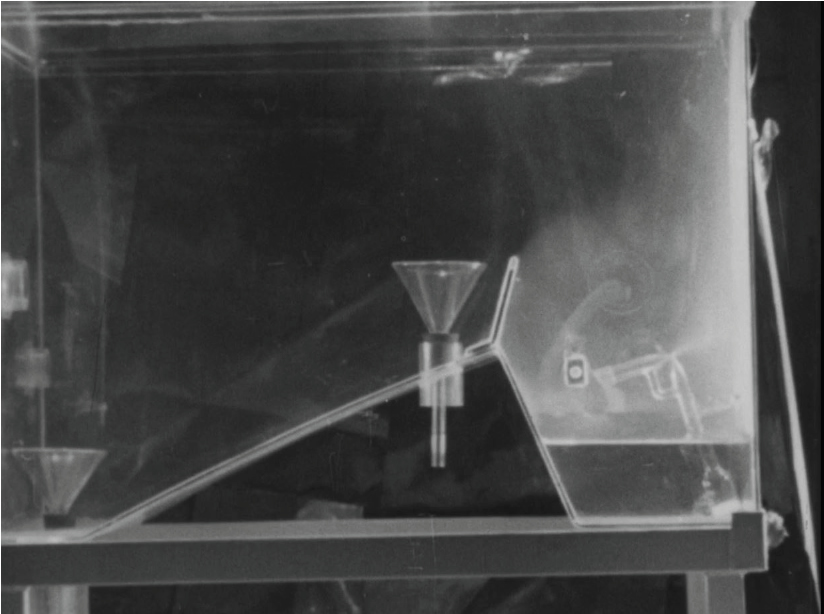

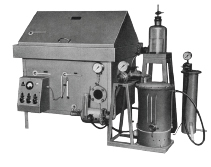

The first salt spray test instrument was delivered to the U.S. military base in Zama. The test chamber was made of the plate glasses, and salt solution that is heated up in an enamel tray inside the chamber was sprayed from the nozzle to the chamber wall. (Bouncing salt solution against the wall method).

It was fortunate for Japanese people that Mr. Robinson was the general manager of goods contract inspection in GHQ. He might have sympathized with an unfortunate situation that Japanese are disadvantaged no matter how much they work. He gave us support by using all resources of the Engineering Department. (omission)

Why did you change the salt concentration from 20% to 5%? How was the test result changed?― Mr. Robinson gave us the data immediately. -We also wanted to know how to measure the particle size ejected from 0.02-inch and 0.05-inch holes and how the error in the diameter of this hole affects the test results. We were simply surprised at his answer. This test method did not exist in Japan at that time; however, it had been standardized and used for 20 years in the U.S.A.

(Cited from Nagaichi Suga, “Jitomyo No.2” The story of a weather meter)

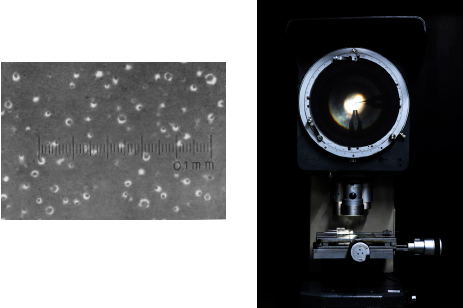

In order to generate homogeneous salt solution sprayed particles which influence the accuracy of a salt spray test, it is necessary that salt solution and the nozzle tip of compressed air are at right angles to one another. This form was created by the glassworks artisans.

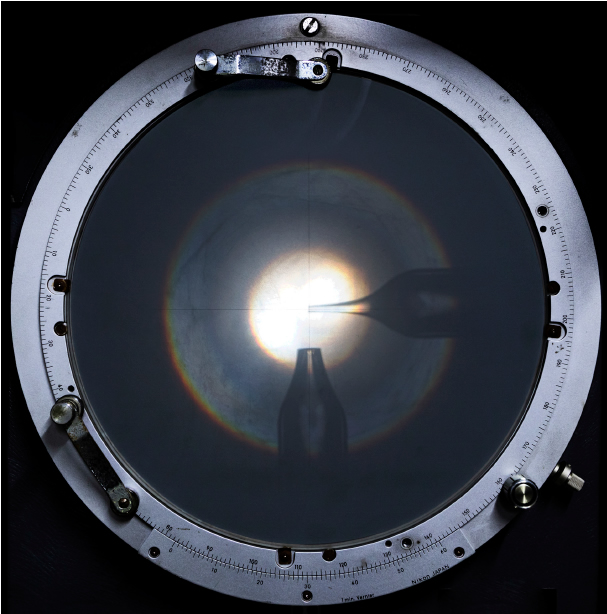

In 1960, the first colourcast was started in Japan. In the following year, the colour test using our automatic colour meter for colour television was started in the control room in TV station. We contributed to the spread of colour management by enabling color measurement which needs complicated calculation with one button.

In measuring colour, what is the standard? ― it was a big proposition when the colour standard did not exist in Japan. We sought the colour standard overseas in order to develop world-class colour meters.

In 1980, Shinjuku was the base for manufacturing until the construction of our factory in Hidaka-cho, Saitama Prefecture (at the time). We have developed, manufactured and sold test instruments and measuring instruments that have never existed in Japan mainly in weather test instruments, corrosion test instruments, and colour meters.